LEARNING ABOUT ESD DISPOSABLE GLOVES

Everyone has experienced electric discharge by touching an object or something else. This is called an Electrostatic Discharge (ESD).

Whilst in daily life these effects are mostly inconsequential, ESD can be very harmful or even dangerous in the industrial world. Learning about ESD disposable gloves is of paramount importance and will help in the selection of gloves with good ESD properties.

ESD ISSUES

In the electronic, semiconductor or nanotechnology industries for example, the release of an uncontrolled spark may cause irreversible damages to electronic devices leading to serious financial losses. In other areas such as the pharmaceutical industry, avoiding electrostatic discharges is of utmost importance to prevent the risk of fire or explosion in potentially explosive atmospheres (ATEX zones). This is essential for the protection of workers against potentially serious or irreversible damage.

When it’s necessary to wear disposable gloves in cleanrooms or laboratories, key considerations may be as follows:

- Limiting static electricity generation from the glove, which could be a source of possible sparks.

- Directing the static electricity current from the gloves to the ground via the body or via a conductive element.

As it is important to select ESD disposable gloves adapted to your activity, it is helpful to understand how static electricity is generated as well as the principle of electrostatic discharge.

UNDERSTANDING ESD WITH SOME USEFUL DEFINITIONS AND CONCEPTS

ESD, Electrostatic Discharge

When static electricity builds up by direct contact or induced by an electrostatic field, the rapid transfer of this charge between the bodies with different voltage potentials is called “electrostatic discharge”.

ESD Generation

Usually, the charge flows as a spark between the two bodies with different electrostatic potentials (voltage). Charge can be generated by either:

- When dissimilar dissipative /insulative materials are rubbed against each other and quickly separated (e.g., rubbing, wiping, flow of liquids, walking and running), this is called tribocharging.

- When one object is negative (electrons) and the other one is positive or the other way around (inductive separation).

Grounding (or earthing)

Ground (or earth) is the reference point in an electrical circuit from which measurements can be performed. When a conductive bridge is created, Earth typically acts to neutralize opposite charges. If there is a conductive connection to earth between charged people or the charged clothing of a person, these charges get neutralized. Under normal conditions (Earth negatively charged), charges flow to earth.

Resistivity measurement test methods

Resistivity is a property that describes the extent to which a material opposes the flow of electric current through it. It is dependent on the type of material and environment. The lower the measurement, the better it is for ESD glove.

There are 3 key test methods:

- Surface (flow of electricity across the surface of the material).

- Vertical (flow of electricity through the material).

- In-use (flow of electricity for example when the hand is in the glove).

“Surface resistivity” (measured in ohms (Ω) – EN 1149-1:2006) is easy to measure but not so relevant for gloves. Indeed, it depends on the material and the level of surface contamination. As the electricity runs along the contamination and not along the surface of the material: The higher the surface contamination the better the surface resistivity. Therefore, surface resistivity may have limited relevance for the application of gloves in cleanrooms.

“Vertical resistivity” measures (according to EN 1149-2:1997) how easy a charge moves through the material. Bear in mind that with higher surface resistance and lower vertical resistance, the charge follows the path of least resistance which is through the material and conducts safely to ground.

Finally, with “In-use resistivity”, the ESD performance of a nitrile glove will seriously improve during its usage. It relates to a higher level of humidity (perspiration). This phenomenon is rarely considered during the ESD glove selection process.

Difference between insulative, conductive and static dissipative gloves

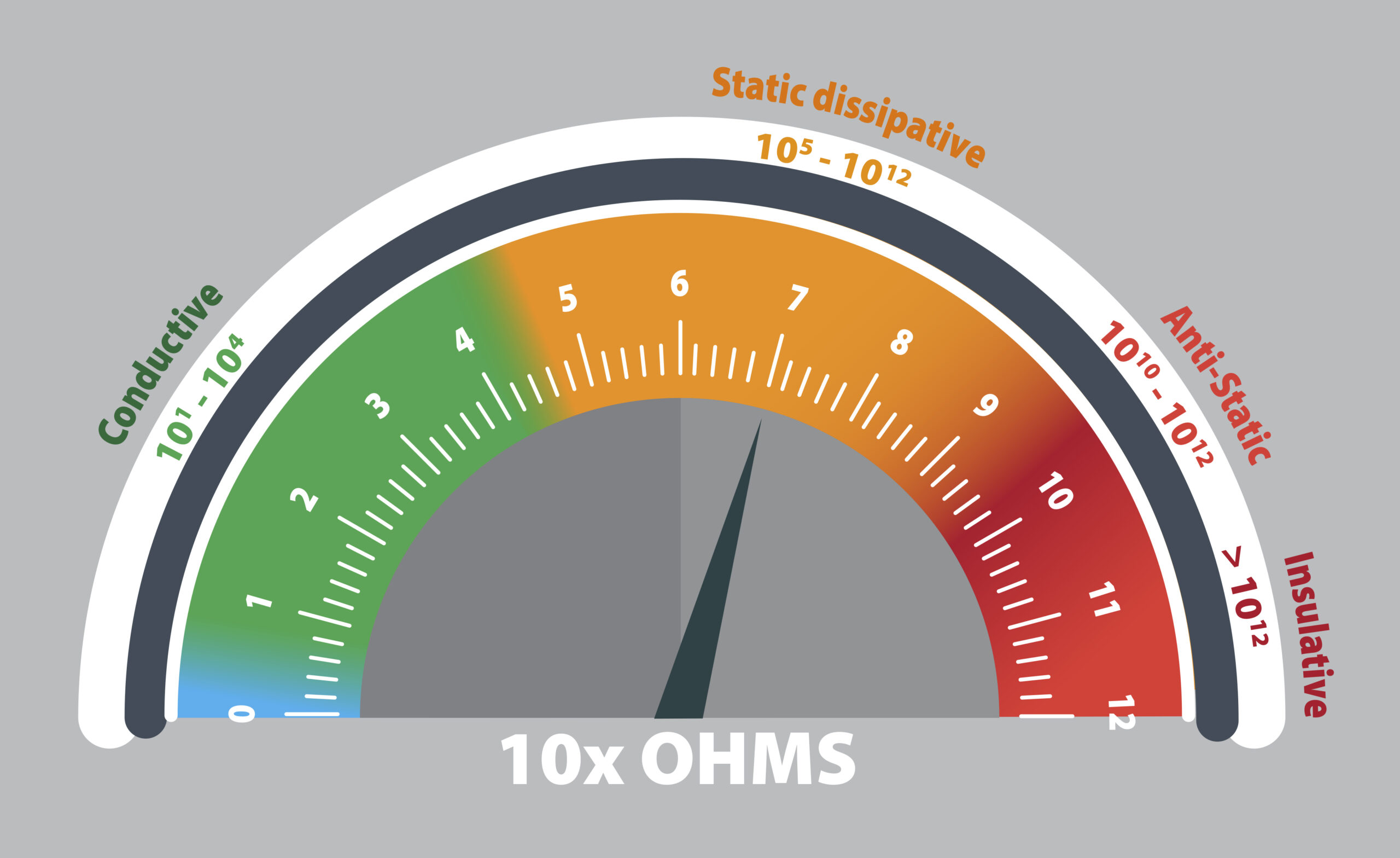

When the resistivity value is < 104 Ω, it’s considered a “conductive” material (fast movement of electricity).

When resistivity value is between 104 and 1011 Ω, it’s considered a “static dissipative” material (slow movement of electricity). Dissipation occurs along the path of least resistance (through the disposable glove to the body and then to the ground).

When the resistivity value is > 1012 Ω, it’s considered an “insulative” material (little or no movement of electricity).

The generic term “Anti-Static” is also widely used and is a source of confusion for the uninitiated. In fact, with a resistivity value of between 1010 and 1012 Ω, a glove could be considered “Anti-Static”. In other words, it is a Static Dissipative glove with a poor ESD performance and closed to being considered insulative.

Charge decay and decay time

The migration of the charge across or through a material leads to a reduction in charge density or surface potential at the point where the charge was deposited. Static decay measures the time it takes to remove a charge to ground (EN 1149-3:2004). Decay time is the time required for an electrostatic potential to be reduced to a given percentage of its initial value. THE FASTER THE BETTER!

REMEMBER: Good vertical resistance associated with a fast decay time is the appropriate combination for an ESD glove!

FOCUS ON TRIBOELECTRIC CHARGE

There are many factors that influence Tribocharging such as walking across a vinyl floor, a synthetic carpet, picking up a polyethylene bag, shrinkable film on PC board etc…and as an operator or quality manager for example, there are questions you should ask yourselves such as:

- How large are the contact areas?

- How fast do the two materials move against each other?

- Where do the two materials occur in the Triboelectric Series?

- Are the surfaces rough or smooth?

- How much pressure is pressing the materials together?

And, regarding ESD disposable gloves, the key factors you should consider are:

- What is the humidity level?

- What are the disposable gloves made of (material)?

- How clean are the materials?

CAUTION:

There is no generic standard to define the ESD performance of a disposable glove.

At present, there is the standard EN 1149-5:2019 “Material performance and design requirements” for dissipative protective clothing BUT gloves are excluded! Furthermore, when considering ESD performance in protective gloves used in explosive or inflammable areas, we refer more and more to ATEX performance requirements. In this context the EN 16350:2014 standard goes beyond the EN 1149-2:1997 standard. While using the same test method, the EN 16350:2014 standard sets the performance requirements for the vertical resistance properties of a glove: Rv< 1.0 × 108 Ω.

THE WAY TO KEEP ESD UNDER CONTROL

As already noted, there are several factors leading to ESD generation.

But some details can also impact the anti-ESD performance

- Wrist straps

- Shoes worn under the garment (a daily check is recommended)

- Plastic connector straps

- Type of under garment clothing

- Fit of the garment

- Type of chair used

- Hair style

- …and the TYPE OF DISPOSABLE GLOVES USED!

Wear a wrist strap when seated and a foot strap on both shoes, whilst a daily check or continuous monitoring are recommended. ESD protective (anti-static) garment such as a grounded sleeve is also recommended.

To reduce the risks related to disposable gloves, proper precautions should be respected

- Use the right gloves size: the better a glove fits, the better the electrical contact and therefore the faster the spark goes away.

- Bear in mind that electrostatic properties are material AND humidity dependent.

- Use Nitrile disposable gloves: Nitrile is the material of choice for ESD and cleanliness sensitive applications.

- Consider all test results of a glove tested in accordance with EN 1149-1:2006, EN 1149-2:1997 and EN 1149-3:2004.

- … and remember that ESD works only when a person is earthed correctly!

ESD gloves are safety equipment recommended for working in most laboratories, cleanrooms etc… and must be used in conjunction with other type of protection to minimize the risk of electrostatic discharges.

ESD NITRILE GLOVES: THE BEST COMPROMISE

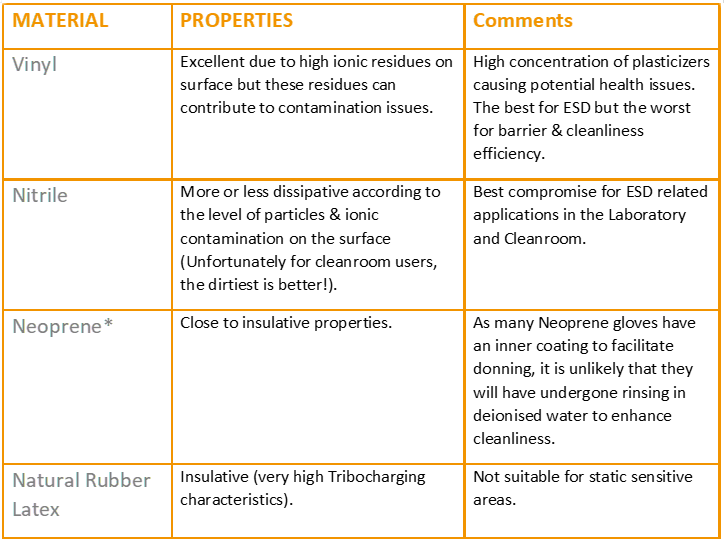

Glove materials have a significant bearing on ESD. The most frequently encountered glove materials and their properties are:

*Several SHIELD Scientific gloves are manufactured with a blend of Nitrile/Neoprene. The percentage of Neoprene used in our gloves to improve comfort is small and does not have any impact on their ESD properties.

SELECT SHIELD SCIENTIFIC ESD NITRILE GLOVES

All our nitrile gloves are static dissipative gloves, but they all feature performance differences. To help you select the ESD nitrile glove most adapted to your process, we invite you to contact your SHIELD Scientific Sales Representative. He/She will guide you to choose the best ESD glove suitable for your laboratory or cleanroom environment and he/she will deliver the associated ESD Certificate that includes all measurements (Surface and vertical resistivity and decay time).

For the last 15 years, SHIELD Scientific has endeavoured to offer the best disposable gloves to our customers. Knowing that prevention contamination and ESD issues are crucial in certain activities such as semiconductors or pharmaceutical industries, SHIELD Scientific offers a large range of ESD nitrile gloves ideal for use in cleanrooms and laboratories.

CONSULT OUR GLOVE SELECTION GUIDE TO SELECT THE ESD GLOVE BEST ADAPTED TO YOUR NEEDS.

Share this interesting information