UNDERSTANDING THE TEST METHOD FOR GLOVE DEGRADATION (ISO 374-4:2019)

The norm ISO (International Organization for Standardization) 374-1:2016+A1:2018 requires a degradation test for “… each chemical claimed in the marking and reported in the user instruction” of disposable nitrile or latex gloves. The glove permeation test and the glove penetration test are thus not the only ones required for substantiating the properties of chemical protective gloves. In this article, we will help gloves users and Health & Safety managers to understand the glove degradation test method according to ISO 374-4:2019.

WHAT IS THE CONTEXT FOR THE CHEMICAL DEGRADATION STANDARD?

The standard ISO 374-1:2016+A1:2018 specifies the requirements for gloves claiming protection against dangerous chemicals and micro-organisms. This norm thus specifies that a degradation test is mandatory for chemicals that are detailed on the user instructions.

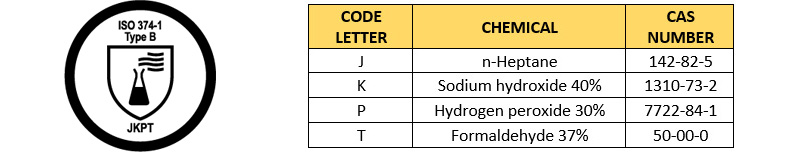

For example, if the below pictogram is marked JKPT then a degradation test is mandatory for the four chemicals* mentioned:

*See Table 2 “List of test chemicals” of the norm ISO 374-1:2016+A1 :2018

This test must be undertaken according to the norm ISO 374-4:2019 which specifies the test method to determinate the resistance to degradation by chemicals of the nitrile and latex gloves.

For more data, please visit our online Chemical resistance guide or contact your sales representative.

WHAT DOES DEGRADATION MEAN?

“Degradation” of a disposable glove is the change in physical characteristics (such as flaking, swelling, disintegration, holes etc…) of a glove due to a continuous contact with a chemical. Degradation can affect the glove material properties compromising its protective performance. This can lead to exposure of lab and cleanroom workers to serious hazards such as skin burns or injuries. The importance of degradation in reducing the protective properties of gloves is particularly relevant to the more corrosive chemicals. Even if a glove achieves a high-performance level for permeation resistance, that may not be enough in terms of providing adequate protection for laboratory or cleanroom workers against chemicals. Indeed, degradation due to continuous contact with chemicals and the conditions under which gloves are used have also to be considered.

WHAT IS THE GLOVE DEGRADATION TEST?

The degradation test evaluates “the resistance of a protective glove material to degradation by a liquid chemical…by measuring the change in puncture resistance of the glove material after continuous contact of the external surface with the challenge test chemical”

(ISO 374-4:2019 test principles).

The test entails puncturing a glove sample after it has been in continuous contact with a chemical for one hour. The amount of force that is required to puncture the glove sample with a stylus is then recorded. Degradation is expressed as a percentage reflecting the change in puncture resistance of the glove material (between the unexposed and exposed test specimens) and is referred to as DR (Degradation Rate).

The lower the percentage, the better the resistance to degradation. In the event of a negative percentage, this could indicate that contact with the chemical has improved the resistance of the glove to degradation. Puncture resistance and glove material appearance are both included in the test results.

IMPORTANT TO NOTE:

- The test is mandatory for all gloves that claim chemical protection and more precisely for each chemical marked and reported in the user instruction.

- The test is applicable to gloves made of natural (Latex) or synthetic polymer (Nitrile, Neoprene…).

- Test results must be detailed in the user instruction notice.

WHAT ARE THE KEY STEPS IN THE GLOVES DEGRADATION TEST?

STEP 1- SAMPLING PHASE

|

Three gloves are randomly selected for testing. From each glove 6 specimens are cut using an arch punch – 3 will be exposed to the challenge chemical and 3 will be unexposed. |

STEP 2 – TESTING PHASE

|

|

PREPARATION OF THE SPECIMENS Vials and vial caps are prepared and labelled. Rubber septa are placed into vial caps. The specimen is placed into the cap with the outer side of the glove facing up. When the cap is placed onto the vial, this side is exposed to the challenge chemical. |

|

|

UNCHALLENGED SPECIMENS TO CHEMICALS The caps with unexposed test specimens are capped onto vials and inverted. |

|

|

SPECIMENS TO CHEMICALS Approximately 2ml of challenge chemical is added to a vial. A cap with a challenge specimen is capped onto this vial. The vial is inverted and placed into the sample holder. The time of this is recorded. |

|

|

After approximately 3 minutes, the challenge chemical can be added to another vial, capped, inverted and the time recorded. This is repeated for all the other challenge specimens and vials. |

> |

|

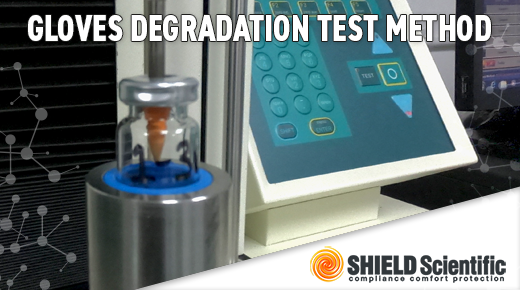

PUNCTURE TEST PREPARATION The H5KS extensometer is set up with a vial holder and spike. The horizon software is loaded with the appropriate method and the sample information is entered. Exactly 60 minutes after exposure, a vial is placed upright, and any visual observations are recorded. The vial is placed into the vial holder and the spike lowered until it rests a few millimetres above the specimen. |

|

|

PUNCTURE TEST The test is started using the software and the spike is lowered until a displacement of 30mm is reached. The test is observed to determine whether the specimen is punctured or not. This is repeated for all challenged vials. Then all unchallenged vials can be punctured (this is not restricted by time). |

STEP 3 – RESULTS PHASE

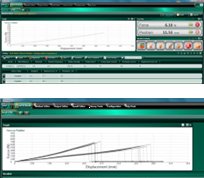

|

When the test is completed, the software will produce a graph of force against displacement and determine the force required to puncture the specimen. For specimens that were not punctured the maximum force recorded is used. The data for the unchallenged vs challenged specimens is used to calculate the degradation of each glove. The three gloves are then compared and used to calculate an overall mean degradation and standard deviation.“THE LOWER THE PERCENTAGE, THE BETTER THE PERFORMANCE” |

WHAT ARE THE LIMITS TO THE DISPOSABLE GLOVE DEGRADATION TEST?

Whilst a test for evaluating changes in physical properties is a positive step, the consistency of this test (possible to have both positive and negative results) plus the focus on puncture resistance may not be relevant to the needs of those working in the laboratory.

It may be prudent to give yourself a safety margin in terms of deciding when to discard gloves and replace them with new ones! The information given is for guidance only and may not reflect the user’s application. A risk assessment should always be made by user to assess the suitability of gloves for a specific application.

Remember that on paper all gloves may comply with the same standards, but as you’ll have noticed they may not offer the same level of performance to permeation and degradation!

SHIELD Scientific provides a wide range of quality disposable nitrile and Latex gloves offering protection against chemical and biological hazards. For more data, please visit our online Chemical resistance guide on our website www.shieldscientific.com.

REQUEST INFORMATION AND SAMPLES NOW!

Share this interesting information