UNDERSTANDING PERMEATION TEST FOR CHEMICAL RESISTANT GLOVES

For better protection of laboratory workers, the highest level of chemical protection should be provided. When we talk about disposable chemical resistant gloves, we are referring to gloves that are designed to protect against chemical hazards. As such, they will have been subjected to different tests: permeation, penetration, and degradation. In this article, we will focus on the permeation test method used for gloves.

WHAT IS THE CONTEXT TO THE EU CHEMICAL PERMEATION STANDARD?

- The standard EN 16523-1:2015+A1:2018 relates to the permeation test method used with Personal Protective Equipment (PPE) gloves.

- It is linked to the ISO 374-1:2016+A1:2018 standard. This standard describes the framework, the performance levels and markings of gloves resistant to chemicals.

WHAT DOES PERMEATION MEAN?

“Permeation” is the process by which a chemical moves through a material at the molecular level.

A priority for laboratory workers seeking the best safety conditions at work is to wear gloves which offer the best chemical permeation test results with the relation to the chemicals being used.

WHAT IS GLOVE PERMEATION TEST?

The “permeation” test measures the barrier effectiveness of latex and nitrile gloves to exposure from a liquid chemical according to the EN 16523-1:2015+A1:2018 standard.

The permeation test provides information on the breakthrough time.

It is a useful method for evaluating the barrier effectiveness of a glove when immersed in a liquid chemical under conditions of continuous contact and at room temperature (23°C +/-1).

It measures how quickly a liquid chemical moves through the glove material.

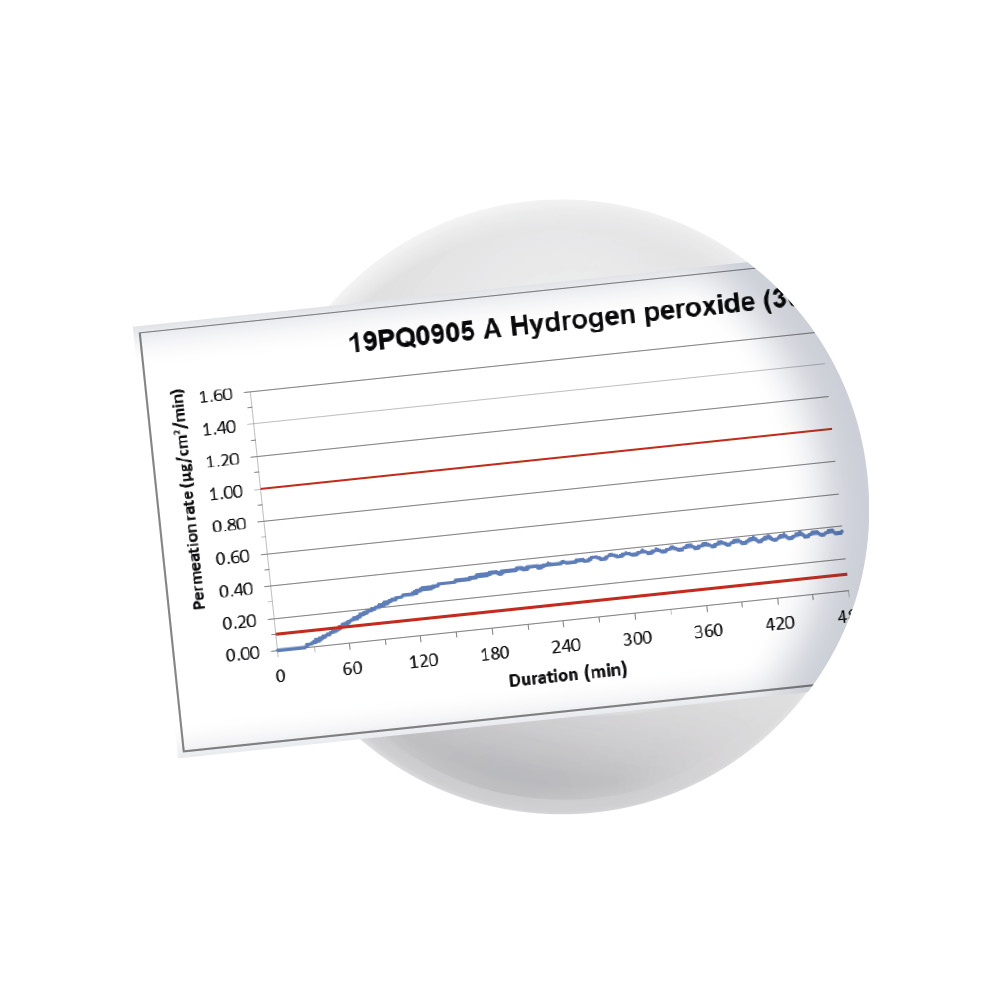

The normalised permeation rate is defined as 1μg/min/cm² and the maximum duration for the test is 480 minutes. Test results are reported based upon the Normalized Breakthrough Time (NBT) achieved.

WHICH CHEMICALS ARE TESTED?

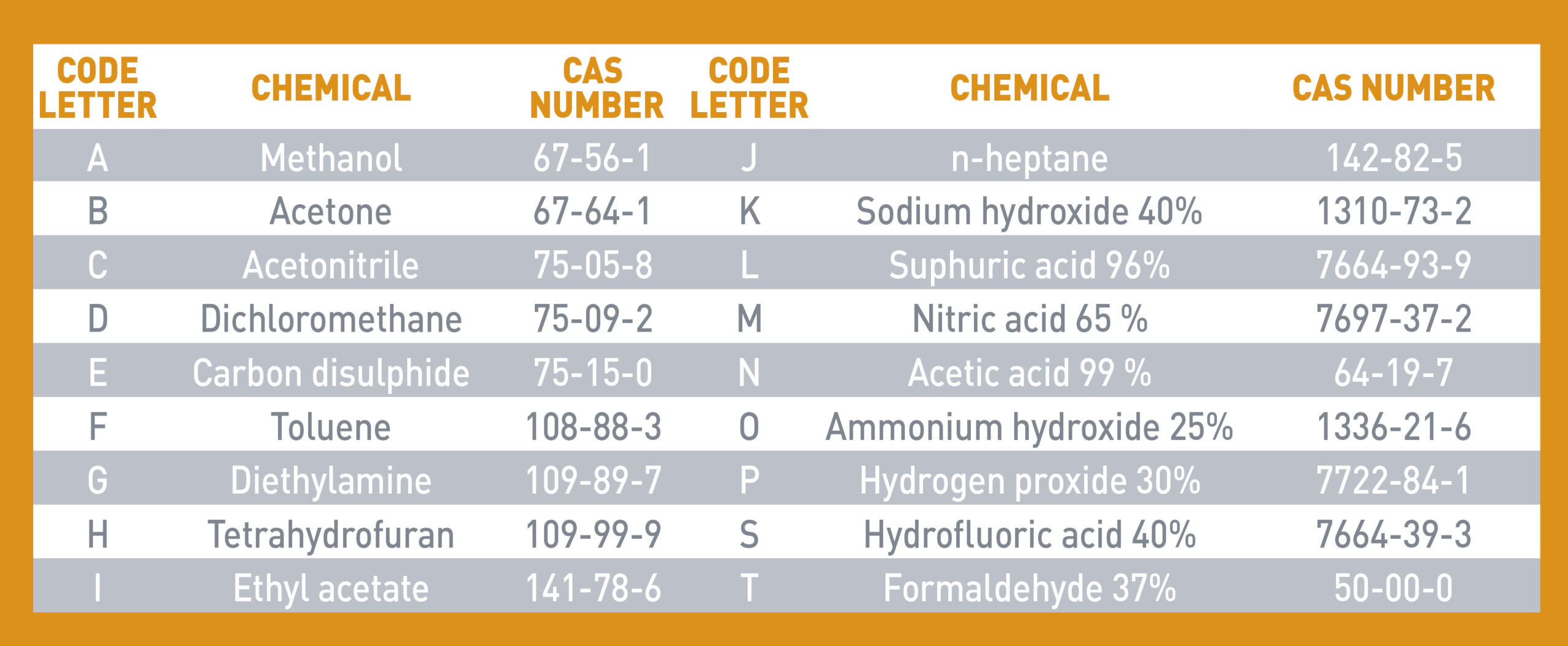

A list of 18 chemicals are specified in ISO 374-1:2016+A1:2018 (see below) and represent the requisite test chemicals.

At SHIELD Scientific, we strongly believe that types (A,B or C) or performance levels (from 0 to 6) are not enough information for choosing the right glove for your protection against chemicals.

That is why we will always indicate in our documentation the exact breakthrough time for the chemicals tested. Always bear in mind the thickness will have an important impact on the breakthrough time (the thicker the better even if gloves are type A!). Furthermore, we provide an extended Chemical resistance guide on our website where you can search and sort information by chemical, by case number or by glove.

WHAT ARE THE KEY STEPS IN THE GLOVES PERMEATION TEST?

STEP 1- PERMEATION TEST: SAMPLING PHASE

STEP 1- PERMEATION TEST: SAMPLING PHASE

Three test specimens are typically taken from the palm area. If the glove is longer than or equal to 400 mm and if it is claimed that cuff offers protection against the chemical risks, then three additional test specimens shall be taken from the cuff area.

STEP 2 – PERMEATION TEST: TESTING PHASE

STEP 2 – PERMEATION TEST: TESTING PHASE

The permeation cell consists of two compartments, separated by the test specimen. The specimen’s outer surface is in contact with the challenge chemical, whereas the specimen’s inner surface is in contact with a collecting medium.

STEP 3 – PERMEATION TEST: RESULTS PHASE

STEP 3 – PERMEATION TEST: RESULTS PHASE

The breakthrough time is deemed to have occurred when the permeation rate of the challenge chemical reaches the normalized permeation rate (1μg/min/cm²). The result is then reported in minutes. The results of the three tests must be within a range of + or – 20% of the average result for the three samples evaluated. If the three results are not within the defined range, the test must be repeated. In the event of non-conformance, then the results shall not be disclosed. The lowest result of the three samples tested must be declared.

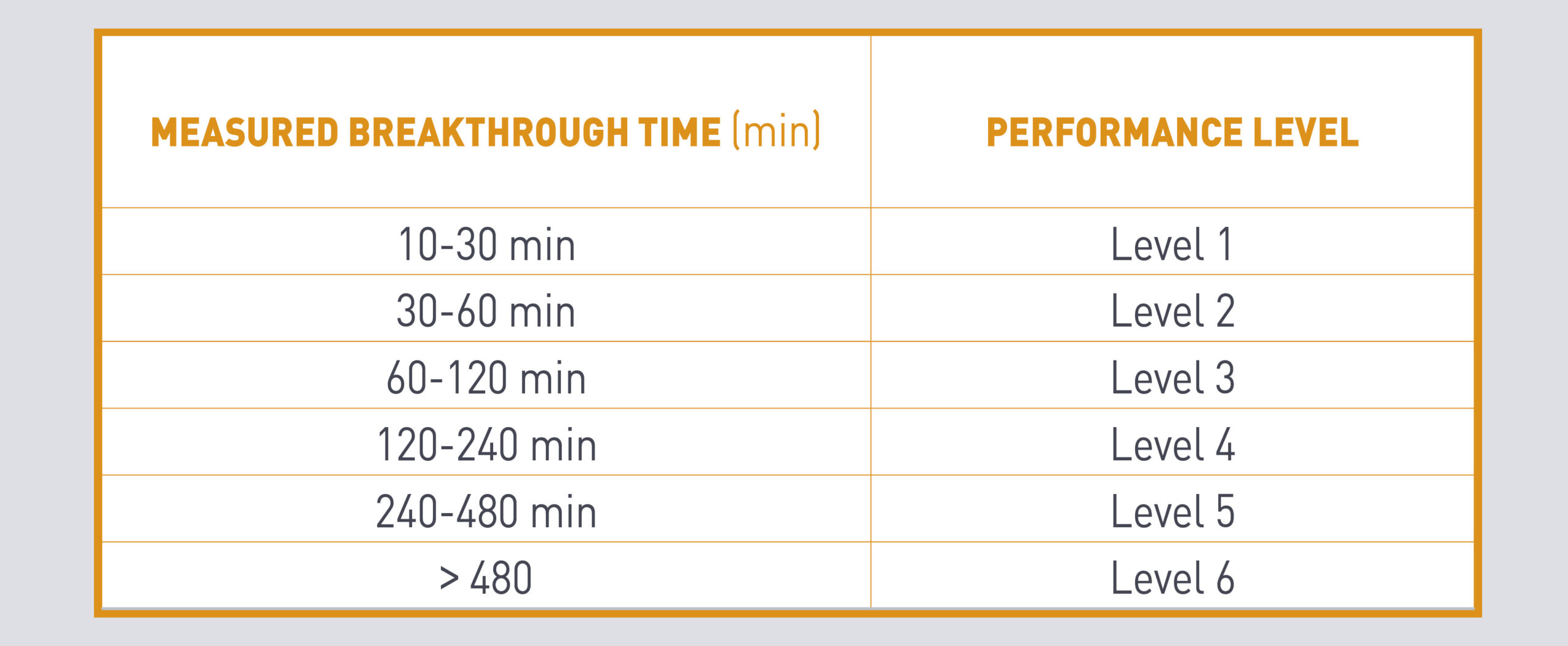

There are six permeation performance levels. Level 6, which is the highest, shows a breakthrough time greater than 480 minutes.

HOW ARE CHEMICAL PROTECTIVE GLOVES CLASSIFIED?

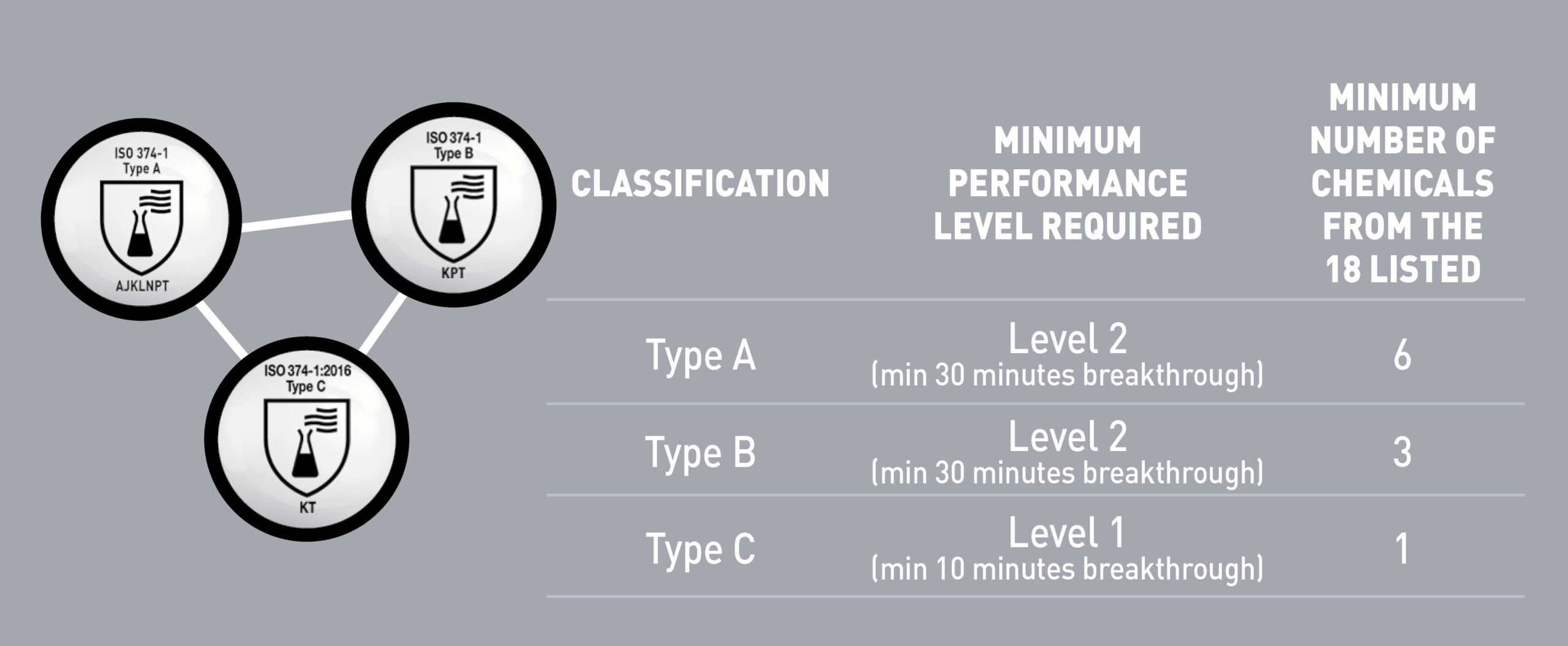

Gloves are classified as type A, B or C depending on their performance level when tested against a number of test chemicals (as outlined in ISO 374-1:2016+A1:2018).

WHAT ARE THE LIMITS TO THE DISPOSABLE GLOVE PERMEATION TEST?

“HIGHER TEMPERATURE CAN MAKE THE BREAKTHROUGH TIME SHORTER”

It should be noted that physical stress is not considered when testing the glove and that a higher ambient temperature or higher chemical concentrations can make the breakthrough time shorter.

Additionally, as body temperature is around 37°C, the temperature experienced by the disposable glove will rise during its use. This will impact on the effectiveness of the glove barrier. It is evident that temperature has a significant influence on the result. Therefore, it may be prudent to give laboratory workers a safety margin in terms of deciding when to discard gloves and replace them with new ones!

The information given is for guidance only and may not reflect the user’s application. A risk assessment should always be made by the user to assess the suitability of gloves for a specific application. Note that the test method according to ASTM F739 is similar but the rate is defined as 0.1μg/min/cm². Therefore, with a lower rate, gloves tested against this US Standard with the same chemical/same % are likely to feature a poorer result. Last but not the least, the classification considers only 18 chemicals.

Most of the time the chemicals used in the laboratory are not part of this list, so whether a glove is Type A, B or C may have limited application for these users.

SHIELDskin CHEM™ NEO NITRILE™ 300 GLOVES, THE BEST CHEMICAL PROTECTION IN THE LABORATORY!

In response to laboratory workers demand for a glove offering a higher level of chemical protection in the laboratory but without compromising dexterity and comfort, SHIELD Scientific has developed the SHIELDskin CHEM™ range of neoprene/nitrile gloves. The twinSHIELD™ technology provides double-walled barrier protection (two materials, two layers and two colours) to achieve better performances. Apart from being registered according to Regulation (EU) 2016/425 as Personal Protective Equipment Category III (Complex Design), SHIELDskin CHEM™ NEO NITRILE™ 300 gloves are Type A and as such offer the highest level of chemical protection. In this respect, the gloves have achieved a minimum breakthrough time of thirty minutes in at least six of the eighteen chemicals listed in ISO 374-1:2016+A1:2018.

REQUEST INFORMATION AND SAMPLES NOW!

For more data, please visit our online Chemical resistance guide on our website www.shieldscientific.com.

Remember: on paper all gloves may comply with the same Standards. But, as you’ll have noticed they may not offer the same level of performance!

At SHIELD Scientific we believe that THE THICKER AND LONGER THE GLOVE, THE BETTER YOU WILL BE PROTECTED!

Share this interesting information

STEP 1- PERMEATION TEST: SAMPLING PHASE

STEP 1- PERMEATION TEST: SAMPLING PHASE STEP 2 – PERMEATION TEST: TESTING PHASE

STEP 2 – PERMEATION TEST: TESTING PHASE STEP 3 – PERMEATION TEST: RESULTS PHASE

STEP 3 – PERMEATION TEST: RESULTS PHASE